FDA Generic Drug Surveillance: What You Need to Know About Safety and Quality

When you pick up a FDA generic drug surveillance, the system the U.S. Food and Drug Administration uses to track the safety and quality of generic medications after they’re approved. It’s not just paperwork—it’s the frontline defense against faulty pills, contaminated batches, and drugs that don’t work like they should. Every time you buy a generic version of a brand-name drug, this system is quietly checking whether what’s in the bottle matches what’s on the label.

Generic drugs are supposed to be exact copies of brand-name medicines, but that only works if they’re made right. That’s where FDA inspections, on-site visits to manufacturing plants, both in the U.S. and overseas, to verify compliance with safety standards come in. The FDA doesn’t wait for complaints—they send teams to factories, review records, and test samples. When they find problems—like dirty equipment, falsified data, or poor quality control—they shut down production. Between 2015 and 2023, over 40 foreign plants were banned from exporting generics to the U.S. because of these inspections.

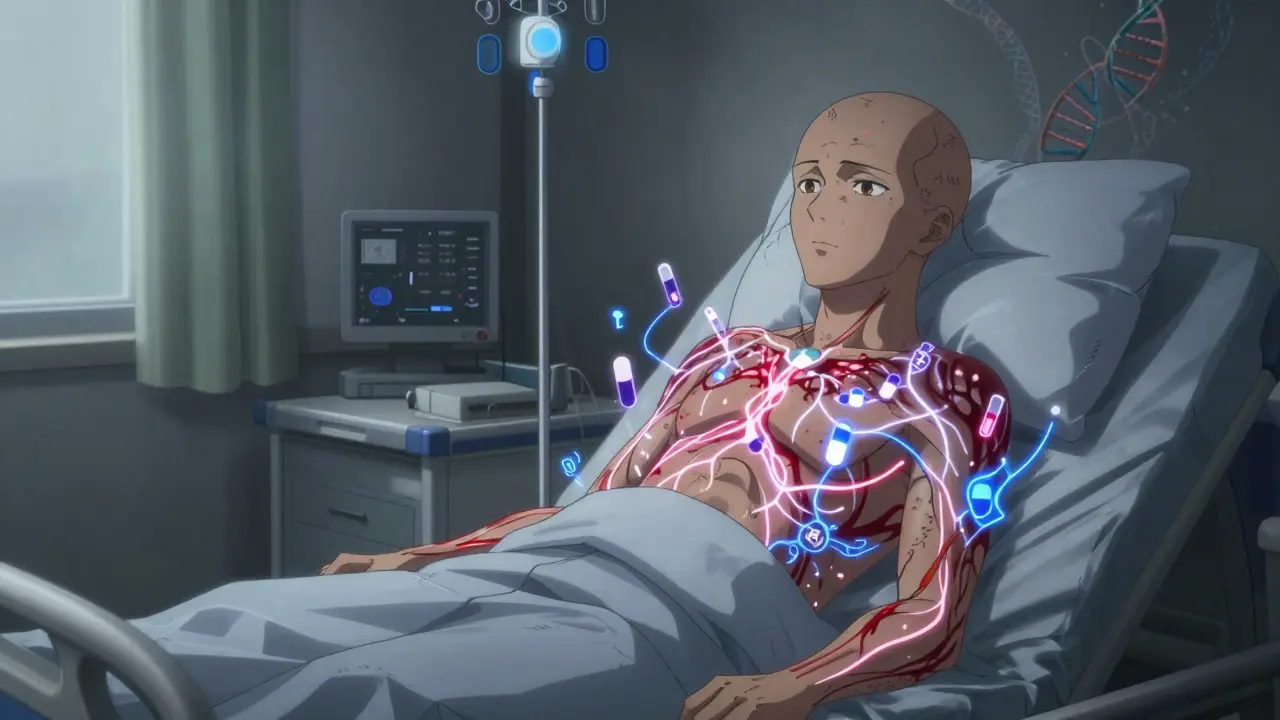

But surveillance isn’t just about catching bad actors. It’s also about understanding how generics behave in real life. bioequivalence, the scientific standard proving a generic drug absorbs into the body at the same rate and amount as the brand version is checked before approval, but the FDA keeps watching after the drug hits shelves. Are patients reporting unexpected side effects? Are certain batches causing more allergic reactions? Are pharmacies switching to cheaper versions that aren’t performing the same? These are all part of the surveillance loop.

It’s not perfect. Some quality issues slip through, especially when manufacturing is outsourced to countries with weaker oversight. That’s why generic drug quality, the real-world performance and consistency of generic medications, not just their approval status matters more than ever. A pill might pass lab tests but still cause problems if the filler ingredients vary or the coating breaks down too fast. That’s why some patients notice differences—even when the active ingredient is identical.

The good news? You don’t have to guess. The FDA publishes inspection reports, recalls, and safety alerts. You can look up your drug’s approval history, check if it’s been flagged, and even see which plant made it. Most people never do, but knowing where to find this info gives you real control. If your generic suddenly stops working or causes new side effects, it’s not just in your head—it could be a change in the manufacturer or formulation. The FDA’s surveillance system is built to catch that, but it needs you to speak up.

Below, you’ll find real stories and data about how generic drugs are monitored, where things go wrong, and how to protect yourself. From manufacturing defects to price-driven substitutions, these posts break down what the FDA sees—and what you should know before your next prescription fills.

Post-Market Surveillance: How the FDA Monitors Generic Drugs After Approval

The FDA doesn't stop monitoring generic drugs after approval. Using FAERS, Sentinel, and AI tools, they track safety, catch hidden risks, and act when problems arise-ensuring millions of daily users stay protected.