Manufacturing Defects in Medications: What You Need to Know

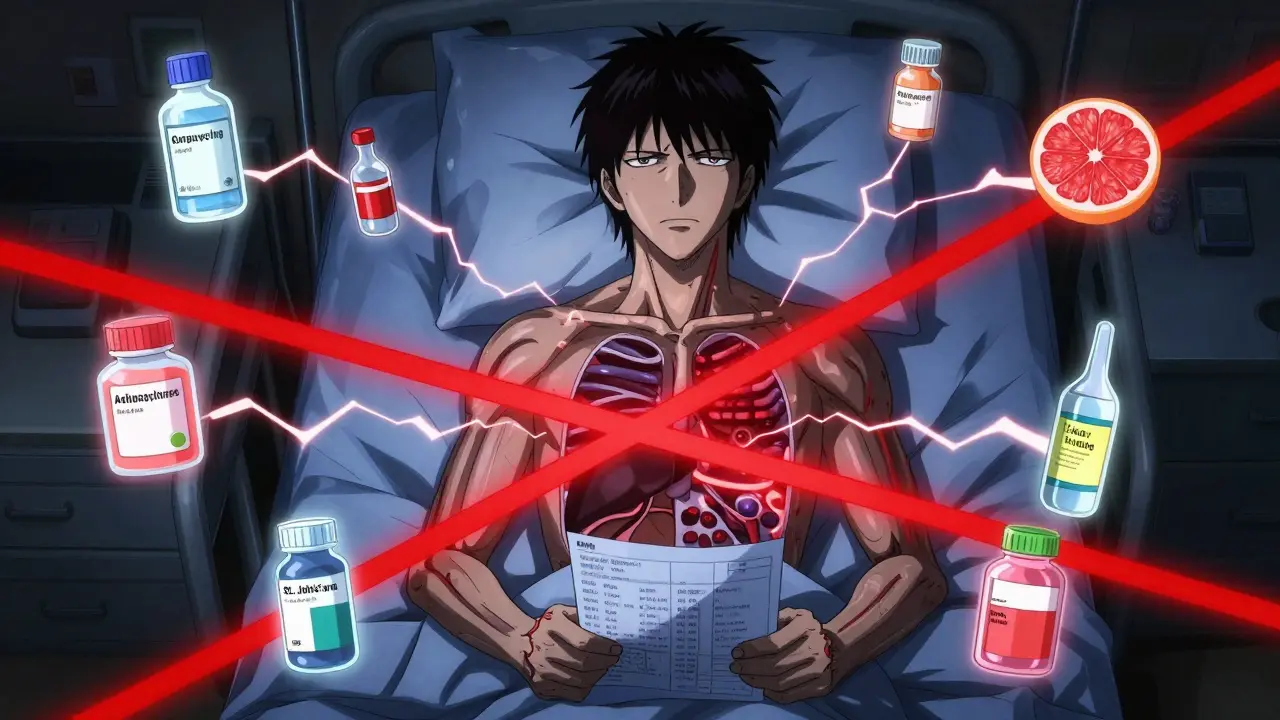

When you take a pill, you expect it to work the way it should—no surprises, no hidden dangers. But sometimes, manufacturing defects, flaws introduced during the production of a drug that can affect its safety, potency, or purity. Also known as production errors, these issues can mean a pill contains too much or too little active ingredient, has foreign particles inside, or breaks down too fast in your body. This isn’t just a theoretical risk. The FDA recalls thousands of medication batches every year because of these problems, from contaminated antibiotics to pills that crumble before they reach your mouth.

Generic drugs, lower-cost versions of brand-name medications that must meet the same FDA standards for safety and effectiveness. Also known as bioequivalent drugs, they are supposed to be identical to the original—but even small mistakes in mixing, packaging, or quality control can break that promise. That’s why the FDA requires bioequivalence studies, rigorous tests that prove a generic drug behaves the same way in the body as the brand-name version. If a batch fails these tests, it shouldn’t be sold. But not every defect shows up in the lab. Some only appear after thousands of people take the drug—like when a coating dissolves too quickly, or a preservative breaks down and lets bacteria grow.

These aren’t rare events. In 2021 alone, over 200 drug recalls were linked to manufacturing issues, including pills with metal fragments, wrong dosages, and even tablets labeled as one drug but containing another. It’s why you need to pay attention to your meds: Is the color or shape different? Does it taste odd? Did your pharmacy switch suppliers without telling you? These are red flags. And if you’re on a critical drug—like blood thinners, thyroid meds, or epilepsy treatments—small changes can be dangerous. That’s why the FDA tracks drug safety, the ongoing monitoring of medications after they’re approved to catch hidden risks so closely.

Manufacturing defects don’t always come from big companies. Even small labs can cut corners under pressure. That’s why knowing your drug’s source matters. You can check the FDA’s Drugs@FDA database to see if your medication has had past recalls or approval issues. And if you’ve had an unexpected reaction, report it—your report could help stop a bad batch before it hurts someone else.

Below, you’ll find real-world examples of how manufacturing flaws, regulatory gaps, and hidden risks show up in common medications—from generic versions of life-saving drugs to supplements that cross the line into dangerous territory. These aren’t hypotheticals. They’re stories of real people, real mistakes, and what you can do to stay safe.

Generic Drug Quality Issues: Manufacturing Plant Problems Explained

Generic drug quality issues stem from manufacturing defects in overseas plants, leading to recalls, ineffective medications, and patient harm. Learn how cGMP violations, foreign inspections, and cost-cutting create risks - and what you can do.