The Environmental Impact of Calcium Acetate Production

The Importance of Calcium Acetate in Our Lives

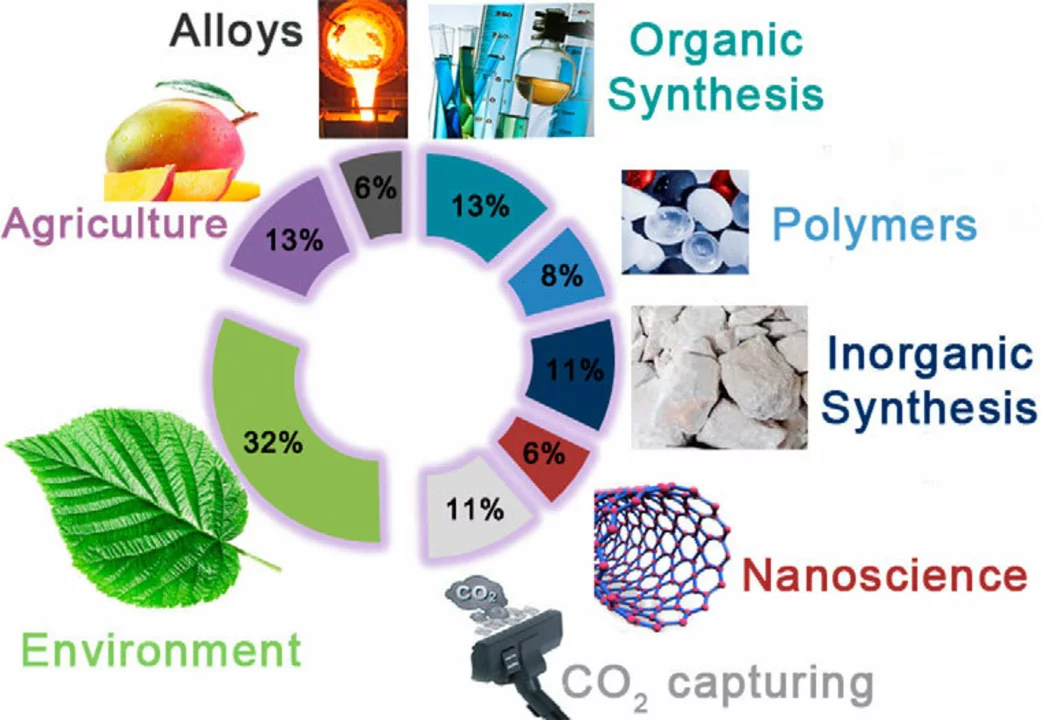

Calcium acetate is a widely used chemical compound with various industrial and commercial applications. From food preservation to the production of concrete, this versatile substance plays an essential role in our daily lives. In this section, we will discuss the importance and applications of calcium acetate, which will help us understand why it is crucial to evaluate its environmental impacts.

Calcium acetate is commonly used as a food additive, acting as a preservative, acidity regulator, and sequestrant. It helps maintain the freshness, flavor, and texture of a wide range of food products. In the medical field, calcium acetate is used as a phosphate binder in patients with kidney disease, helping to control high phosphate levels in the blood. It is also found in various pharmaceutical and cosmetic products.

In the construction industry, calcium acetate is used as a concrete setting accelerator, improving the strength and durability of concrete structures. Additionally, it is used in the production of water-resistant materials, such as water repellent coatings and waterproofing agents. With all these applications, it is clear that calcium acetate plays an important role in modern society.

Understanding the Production Process

To assess the environmental impact of calcium acetate production, we must first understand the manufacturing process. Calcium acetate is typically produced through the reaction of calcium carbonate with acetic acid. This process generates calcium acetate and carbon dioxide as byproducts. Alternatively, it can be produced through the reaction of calcium hydroxide with acetic acid, resulting in calcium acetate and water.

These production processes require the use of raw materials, such as calcium carbonate (limestone) and acetic acid, which are obtained through mining and chemical manufacturing, respectively. The extraction and production of these raw materials also come with their environmental impacts, which we must consider when evaluating the overall environmental footprint of calcium acetate.

Emissions and Air Quality Concerns

One of the primary environmental concerns associated with calcium acetate production is air pollution. The manufacturing process releases carbon dioxide (CO2), a greenhouse gas that contributes to climate change. Additionally, the production of acetic acid, a raw material required for calcium acetate synthesis, generates hazardous air pollutants, such as volatile organic compounds (VOCs) and particulate matter.

These air pollutants can have negative effects on both the environment and human health. For instance, VOCs contribute to the formation of ground-level ozone, a harmful air pollutant that can cause respiratory issues and exacerbate existing health conditions. Particulate matter, on the other hand, can lead to reduced visibility, acid rain, and various respiratory and cardiovascular problems.

To mitigate these air quality concerns, calcium acetate manufacturers must implement pollution control measures, such as installing emission control devices and using cleaner production methods. Additionally, companies can invest in research and development to discover more environmentally friendly alternatives to calcium acetate.

Water Usage and Waste Generation

Another environmental concern associated with calcium acetate production is water usage and waste generation. The manufacturing process requires significant amounts of water for cooling, cleaning, and as a reaction medium. This high water demand can contribute to water scarcity in regions where the production facilities are located.

Moreover, the production process generates waste in the form of sludge, which contains residual calcium carbonate, acetic acid, and other impurities. If not properly managed, this waste can contaminate water sources, posing risks to aquatic ecosystems and human health. To address these concerns, calcium acetate manufacturers must implement water conservation and waste management practices, such as recycling and reusing water, treating wastewater before discharge, and finding alternative disposal methods for waste materials.

Energy Consumption and Greenhouse Gas Emissions

The production of calcium acetate is an energy-intensive process, requiring significant amounts of heat and electricity. This high energy demand contributes to greenhouse gas emissions, particularly if the energy is derived from fossil fuels. To reduce their carbon footprint, calcium acetate manufacturers can invest in energy efficiency measures, such as using energy-efficient equipment, optimizing production processes, and integrating renewable energy sources into their operations.

Furthermore, companies can participate in carbon offset programs to compensate for their unavoidable emissions. These programs involve investing in projects that reduce greenhouse gas emissions, such as reforestation, renewable energy development, and energy efficiency improvements.

Occupational Health and Safety Concerns

The production of calcium acetate also poses occupational health and safety risks to workers in manufacturing facilities. Exposure to chemicals, such as acetic acid, can cause skin, eye, and respiratory irritation. Furthermore, the handling of raw materials and waste can result in accidents, injuries, and long-term health issues.

To protect worker health and safety, calcium acetate manufacturers must implement strict safety protocols, provide adequate personal protective equipment, and ensure proper training in the handling and disposal of hazardous materials. Additionally, companies can promote a culture of safety by encouraging employee involvement in safety initiatives and conducting regular safety audits.

Conclusion: Striving for Sustainability

Calcium acetate is an essential compound with numerous applications in various industries. However, its production comes with significant environmental impacts, such as air pollution, water use, waste generation, and greenhouse gas emissions. To minimize these impacts, calcium acetate manufacturers must adopt sustainable practices, invest in cleaner production methods, and explore alternative materials with lower environmental footprints.

As consumers, we can also contribute to reducing these impacts by making informed choices and supporting companies that prioritize environmental and social responsibility. By working together, we can help ensure a sustainable future for calcium acetate production and its many applications in our daily lives.

Comments

Leilani Johnston

May 30, 2023 AT 01:00Honestly, I never thought about how much goes into making something as simple as calcium acetate. It’s everywhere - in our food, our medicine, even our buildings - but we never stop to ask where it came from or what it cost the planet. We’re so used to convenience that we forget the invisible labor behind it.

Maybe we need to start treating chemicals like they’re alive, not just ingredients. They leave footprints. And those footprints? They’re in the air, in the water, in the lungs of people who work in those factories. We owe it to them to do better.

Jensen Leong

May 30, 2023 AT 10:21The environmental calculus of calcium acetate production is non-trivial. While its utility in medical and industrial contexts is well-documented, the lifecycle analysis reveals significant externalities: CO₂ emissions from acetic acid synthesis, energy-intensive processing, and non-recyclable sludge byproducts. A systems-thinking approach is imperative. Regulatory frameworks must incentivize closed-loop water systems and renewable energy integration. Without structural change, greenwashing will persist.

Kelly McDonald

June 1, 2023 AT 05:56Okay, but let’s talk about the *vibes* of this whole thing. 🌱 Calcium acetate is like that quiet neighbor who does everything right - keeps the block clean, fixes your fence, but no one ever asks if they’re tired. We use it to keep our cheese from going bad, our kidneys from failing… but we never ask if the planet’s okay after it’s done its job.

What if we started choosing alternatives not because they’re cheaper, but because they’re kinder? Like, imagine if every time we bought a food additive, we also bought a tree. Or a water filter. Or a safety training course for a factory worker. We could turn chemistry into compassion.

Joe Gates

June 2, 2023 AT 09:02You know, I’ve been thinking about this for days now - not just the science, but the human story behind it. Every molecule of calcium acetate that leaves a factory is tied to someone’s paycheck, someone’s cough, someone’s child who might breathe in the dust from a poorly maintained vent. And yes, it helps people with kidney disease live longer, but at what cost? The cost isn’t just carbon - it’s sleepless nights for workers, it’s rivers that used to be clear, it’s the silence of communities that lost their fish. We need to stop seeing this as a ‘trade-off’ and start seeing it as a moral question. Can we really say we’re civilized if we keep pretending the price tag on convenience doesn’t include our own humanity?

Tejas Manohar

June 3, 2023 AT 05:54The industrial production of calcium acetate necessitates a rigorous adherence to ISO 14001 environmental management standards. Emissions control systems, including scrubbers and catalytic oxidizers, must be mandated by regulatory authorities. Furthermore, energy efficiency benchmarks should be aligned with the EU’s Ecodesign Directive. Without mandatory compliance frameworks, voluntary corporate initiatives remain insufficient.

Mohd Haroon

June 4, 2023 AT 22:54This is not a debate about sustainability - it is a reckoning. The global demand for calcium acetate is rising, yet our regulatory infrastructure is decades behind. China and India now dominate production, with minimal oversight. The environmental cost is being exported to the Global South while Western consumers enjoy the benefits. This is ecological colonialism. We must demand transparency - not just from manufacturers, but from governments that enable it.

harvey karlin

June 6, 2023 AT 04:48LMAO we’re overcomplicating this. Calcium acetate = CO2 + sludge + energy hog. End of story. The fix? Swap it for citrate or gluconate. Same function, 60% lower footprint. Industry’s too lazy to pivot because ‘but the supply chain!’ Nah. Just innovate. We did it with plastic bags. We can do it here. Stop romanticizing the status quo.

Anil Bhadshah

June 8, 2023 AT 01:45I work in a pharma plant that uses calcium acetate. We recycle 90% of our water now. The sludge is dried and used in cement. It’s possible. But only if companies are given tax breaks for green tech. No one will spend money unless it saves them money. 💡💧

Trupti B

June 8, 2023 AT 21:41idk why everyone is so stressed about this like its the end of the world i mean its just a chemical right like we eat it and its fine and if the workers get sick thats their problem

lili riduan

June 9, 2023 AT 19:58I just cried reading this. Not because I’m dramatic - but because I realized I’ve been part of the problem. I bought that ‘natural’ cheese with calcium acetate last week. I thought I was being healthy. But now I know - every bite had a hidden cost.

So I’m switching. I’m asking my grocery store for alternatives. I’m writing to the brands. I’m telling my friends. This isn’t just about chemicals - it’s about waking up. And I’m so glad this post woke me up.

VEER Design

June 10, 2023 AT 09:14The real irony? We use calcium acetate to save kidneys - but the production process is literally poisoning water sources that people rely on for clean drinking water. It’s like using a bandaid to treat a broken leg and then blaming the patient for not healing faster. We need to stop treating symptoms and fix the system. 🌍✊

Leslie Ezelle

June 11, 2023 AT 10:18Enough with the ‘balanced’ takes. This isn’t a ‘discussion.’ It’s a crisis wrapped in a lab report. Companies are lying about emissions. Regulators are asleep. Workers are dying quietly. And you? You’re still buying the cheese. You’re still using the concrete. You’re still silent. Wake up. Or get out of the way.

Dilip p

June 13, 2023 AT 05:51A thoughtful analysis. However, we must recognize that calcium acetate is not inherently harmful - it is the *scale* and *method* of production that pose risks. Small-scale, renewable-powered, closed-loop systems already exist in pilot form in Germany and Japan. Scaling these requires public funding and policy support. Let us not condemn the compound, but demand better systems.